What is In Situ Chemical Oxidation (ISCO)?

What is In Situ Chemical Oxidation (ISCO)?

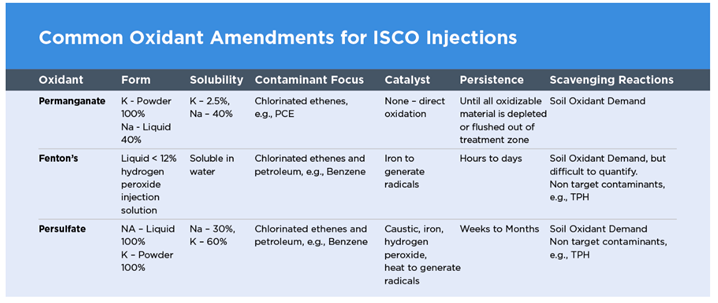

In situ chemical oxidation (ISCO) involves the injection of chemicals into the subsurface to oxidize contaminants. The major oxidants used in remediation are hydrogen peroxide, permanganate, persulfate and ozone. In many cases, the chemical oxidants need to begin oxidizing or reducing contaminants. Common activators include iron, caustic, and heat.

In some cases, remedies are combined for greater effect. Common combinations include hydrogen peroxide and persulfate, and persulfate and permanganate.

ISCO is an efficient and cost-effective remediation technology that provides rapid in situ destruction.

How does ISCO work?

While some oxidants such as permanganate cause direct oxidation of chlorinated ethenes, radical chemistry is the primary mechanism for most oxidation or reduction of contaminants. Hydroxil and sulfate are common radicals used for oxidation, and superoxide is often used for reduction.

Chlorinated ethanes and methanes are primarily destroyed though reduction, whereas chlorinated ethenes and petroleum are destroyed via oxidation.

What are common reasons for using ISCO?

ISCO is an especially useful remediation technology for treating source area contaminants at concentrations below DNAPL or LNAPL conditions.

For compounds like 1,4 dioxane, chemical oxidation is the only commercial remedy available (though research is ongoing for bioremediation approaches).

In some cases, ISCO can be used to reduce the overall remediation timeline (vs. a slower bioremediation approach). However, if the source area has high concentrations of contaminants sorbed to finer grained soils, multiple events over extended time frames will be required to overcome groundwater rebound, which would make the timeframe similar to what you’d expect from a bioremediation solution.

What should I know before starting an ISCO project?

Based on our remediation experience and review of performance monitoring data, we recommend that you:

- Take into account that NAPL or mass sorbed to soils can require multiple applications to liberate and treat.

- Consider hydraulics and ISCO kinetics in the radius of influence design estimates (e.g., injection volumes are too low).

- Use high resolution site characterization (HRSC) and don’t just rely on data derived from monitoring wells, which are insufficient to define target intervals.

- Don’t inject through wells at highly heterogeneous sites.

- Pay close attention to field parameters such as distribution, pressure, flows, tooling and injection approach.

What are the design assumptions for ISCO?

Since ISCO is a relatively short-lived treatment technology, effective design assumptions must address how to dose for mass in the sorbed or DNAPL phases that are not readily available for treatment unless in the dissolved phase. Therefore, the design best practices for ISCO should account for the eventual transition of mass bound up in soil and DNAPL to the dissolved phase. The design phase should not initially overdose by assuming this mass is readily available for treatment.

Why choose ISCO?

Chlorinated ethene sites, especially those in coarse-grained transmissive zones, can be efficiently and cost effectively treated by chemical oxidation using permanganate. Other oxidants can also treat chlorinated ethanes and menthanes, through chemical reduction. suited for injection into coarse grained transmissive zones

Oxidants like hydrogen peroxide, persulfate and ozone are effective treatment options for solvents and for petroleum contamination in transmissive zones.

In some cases where sites are already aerobic, chemical oxidation is considered the preferred approach over trying to turn anaerobic for bioremediation.